At Southwest Quality Molding, we use state-of-the-art injection molding machines to produce premium quality custom plastic parts for customers in a diverse range of industries.

Our climate controlled facility houses presses with 50 to 500 tons of clamping force for handling shot sizes up to 60 oz. We are fortunate to have an in-house mold and part designer, along with our tooling department which allows us to build world-class tooling in-house. Our profound understanding of plastics technology gives us the capacity to work with any type of commodity or engineering resin. Whether your part requires chemical resistance, UV tolerance, or FDA approval, we can specify a material to match your performance requirements. Specializing in miniature to medium sized components, we are capable of achieving industry-leading tolerances with some parts as close as ±0.001″ on injection, insert, or over-molded parts. Our processes are tightly controlled to achieve maximum efficiency, which enables us to keep prices very reasonable.

We operate 24 hours a day to provide rapid turnaround, and we have an outstanding record for on-time delivery. In business since 1980, we are committed to excellence and build quality into everything we produce. More detail about our quality plastic injection molding services can be found in the table below. Please contact us today, we would be happy to supply a quote for your next project.

Project Examples

- Custom Injection Molded Computer Front Bezel Cover

- Custom Injection Molded Plastic In-Store Shelf Signage Tag

- Custom Injection Molded Forklift Pad Pedal

- ABS Plastic Injection Molded Forklift Steering Column Cover

- Custom Plastic Injected Pipe Flow Conditioners

- Custom Injection Molded Nylon Land Exploration Bottom Case

Plastic Injection Molding Capabilities

- Product Capabilities

- Miniature

Small Parts

Medium Parts

Large Parts

Multi-Component

- Mold Process Type

- Injection

Insert

Over Molding

- Material

- ABS

Acetal

Acrylics

Cellulosics

Nylon

Polycarbonates

Polyesters

PEEK®

Polysulfone

Polyethylene

Polypropylene

Polystyrene

SAN

Urethane

Ultem®

Vinyl

And Many More

- Plastic Characteristics

- FDA Approved

Chemical Resistant

Glass Filled

Heat Resistant

High Impact

High Viscosity

Mineral Filled

Talc Filled

Carbon Filled

Weather Resistant

UL Rated

Thin Walled

- Clamping Force

- Minimum of 50 Tons - Maximum of 500 Tons

- Shot Size

- Up to 60 oz.

- Number of Cavities

- Minimum 1 Cavity - Max 32 Cavities

More Depending on Part Size

- Tolerance (+/-)

- As close as ± 0.001 in

*Part and Material Dependent

- Quality/Inspection

- Visual Inspection

CMM Dimensional Inspection

- Additional Services

- Engineering

Foam Molding

Mold Design

Product Development

Rapid Prototyping

Tooling

-In-House Tooling

-Prototype Tooling

-High Production Run Tooling

- Lead Time

- 2 - 3 Weeks

Blanket Orders

J.I.T Deliveries

Emergency Services Available

- Production Volume

- Low Volume

Short Run

Medium Volume

High Volume

Long Run

Large Scale Production Volume Run

Additional Information

- Industry Focus

- Agriculture Automotive Building/Construction Material Handling Consumer Products Electronic

Food

Government

Industrial

Oil Field

Packaging

Sporting Goods

Toys

- Industry Standards

- UL Registered Molder for Electronic Parts

Underwriters Laboratories

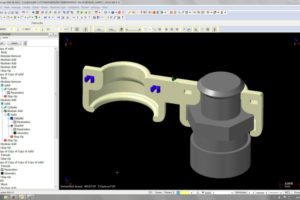

- File Formats

- AutoCAD (DWG,DWZ)

MasterCam (MDX, MC8, MC9, SET)

PDF

STEP

.X_T files

.SLDPRT files