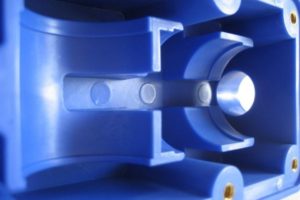

At Southwest Quality Molding, we can produce complex injection molded parts from a wide variety of thermoplastic materials. The part shown here is the bottom of a case that is used by oil companies in a land exploration application. This component is made of 163 grams of high impact nylon with 13 insert molded brass inserts that are used in assembly of the complete case.

The case bottom measures 141.8 mm in length, 57 mm in width, 38.5 mm in height and is produced on a 230 ton Van Dorn injection molding machine. Cam-driven slide core pulls are used to produce the two 15 mm diameter holes that can be seen in the sidewalls of the component. We excel at developing innovative solutions to complex insert molding, overmolding, and coring challenges, while always minimizing costs without sacrificing part quality.

Dimensional and visual inspections were performed to verify conformance to all customer specifications. We can perform inspections and testing, in accordance with all major industry standards and customer specific requirements. For additional information regarding this custom nylon injection molding project, see the table below, or contact us directly.

Custom Injection Molded Nylon Land Exploration Bottom Case Project Highlights

- Product Name

- Bottom Case

- Product Description

- Exploration Land Bottom Case

- Process Type

- Custom Injection Molding; Insert Molding

- Equipment used to manufacture part

- 230 ton Van Dorn Injection Molding Machine

- Over-all Part Dimensions

- 57mm wide x 141.8mm long x 38.5mm high

- Material

- Nylon

- Plastic Characteristics

- High Impact

- In process testing/ inspection preformed

- Dimensional Inspection; Visual Inspection

- Part Weight

- 163 grams

- Industry for use

- Oil Exploration

- Standards

- Customer supplied specifications